Additional Equipment

- Support truck with 100-gallon water capability

- Morooka ATV track mounted support vehicle

- Pulstar Pump Hoist Truck

- Fleet of vacuum excavation rigs

- Fleet of air compressors

Summit Drilling customers are privy to one of the largest and most diverse equipment fleets in the drilling industry. Environmental engineering firms benefit from this wide range of capability, as well as Summit’s ability to address multiple project requirements simultaneously.

Click on any piece of equipment listed below for dimensions, capabilities and brief notations on its use.

MRS-50 (50K Head Roto-Sonic Crawler)

Sonic Drilling Power

- 50k drill head including tilt frame

- 50.000 lbs of sonic output force

- 0-150 Hz Sonic frequency

- 0-140 RPM rotation

- 5,250 ft-lb CW rotation torque @ 0-140 RPM

- 7,000 ft-lb CCW rotation torque @ 0-140 RPM

- 0-90 degr. tilt capacity

Rig

- Limited access track

- Height 34’

- Width 89”

- Weight 40,000lbs

- High pressure water pump 19 l/min @ 210 bar / 5 gpm @ 3,045 PSI

- FMC Bean Mud pump 160 l/min @ 45 bar / 42 gpm @ 652 PSI

- Aluminum water tank 500 liter / 132 gallon

- Mechanical separators among different rod layers

- Casing or drill rod storage – 210’ of 6 5/8 casing

- Fully automated rod or casing handler

Capabilities

- Push Ahead water sampler

- 3.5” rock coring

- 3” Shelby tubes

- 4” continuous 10’ sampling, 6” boring, 2” well to 500’

- 4” continuous 10’ sampling, 8” boring, 4” well to 300’

- 4” continuous 10’ sampling, 10” boring, 6” well to 200’

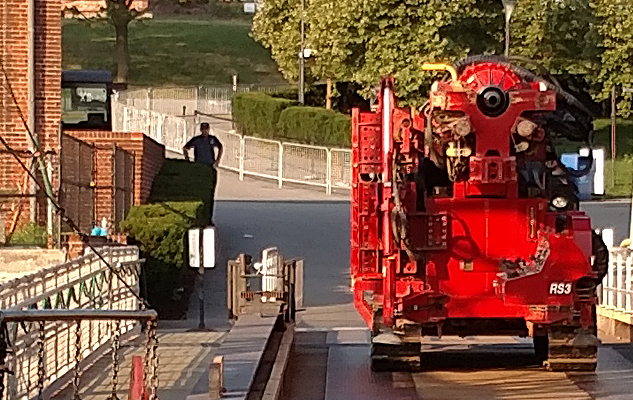

CRS-32 (32K Head Roto-Sonic Crawler)

Sonic Drilling Power

- Sonic vibration oscillator output force 22,480 lbf (synchronized). Frequency 0 – 150 Hz.

- 2 eccentrics, mechanically synchronized

- Rotation torque: clockwise 1,254 ft lbf @ 2,180 PSI, 0-120 rpm

- Rotation torque: anti clockwise 1,475 ft lbf @ 2,450 PSI

Rig

- Limited access track

- Height 33’

- Width 89”

- Weight 30,000lbs

Capabilities

- Push Ahead water sampler

- 3” Shelby tube

- Water pump for AquaLock sampling, 5 gpm @ 3,000 PSI

- Flow pump for drilling, 42 gpm @ 650 PSI

- 3” continuous 5’ sampling, 6’ boring, 2” well to 250’

- 3” continuous 5’ sampling, 8” boring, 4” well to 200’

SRS-20 (20K Head Roto-Sonic Crawler)

- Sonic Vibration Oscillator Output Force 100kN @ 0-150 Hz/22480/22,480

- 2 Eccentrics, mechanically synchronized

- Rotation Torque: Clockwise 1,245ft-lbf @ 2,175 PSI, 0-120 RPM

- Rotation Torque: Counter Clockwise 1,475 ft-lbf @ 2,540 PSI, 0-120 RPM

Rig

- Limited access track

- Height 17.9’

- Width 57”

- Weight 14,000lbs

- Kabuto 4 cylinder water cooled engine 100 hp

- Fuel tank (diesel) 83 litre / 22 gallon

- Load sense hydraulic system

- Control panel on turning arm

- High pressure water pump 19 l/min @ 210 bar / 5 gpm @ 3045 PSI

- Aluminum water tank 300 liter / 79 gallon

- Casing Rack

- Water pump for drilling

- Water tank

Capabilities

- Discrete water sampler

- Water pump for AquaLock sampling, “soft sediment sampling”

- 2” continuous sampling, 4” boring to 100’

- 3” continuous 5’ sampling, 6” boring, 2” well to 100’

(2) Reichdrill T650W-II (Air)

Dimensions: 34’ l x 9’w x 42’h/65,000lbs.

Capabilities: Air Rotary/Mud Rotary

Scenarios of Use

- Deep well installation (~1000’) in consolidated rock formations using percussion hammer or tri-cone bit

(2) Diedrich D-120 (Mud/Auger)

Dimensions: 35’l x 9’w x 35’h/48,000lbs.

Capabilities: Mud rotary, hollow stem augers, with split spoon sampling, rock coring

Scenarios of Use

- Shallow well installation (~200’) in unconsolidated formations using hollow stem augers with split spoon sampling

- Mud rotary to (~300’) with split spoon sampling in unconsolidated formations

- HQ/NQ rock coring to (~600’) in consolidated formations

(4) Geoprobe 7822DT Track (Direct Push)

Dimensions: 11’l x 5’w x 15’h/7,555lbs.

Capabilities: Direct Push (6’ stroke), mud rotary, air rotary, hollow stem auger.

Scenarios of Use

- Rubber track – ideal for off road and in building/facility operations

- Direct push up to 200’ for soil, groundwater investigation

- Shallow well installation (~100’) in unconsolidated formations using hollow stem augers

- Shallow well installation (~50’+) in consolidated formations using air rotary

(3) Geoprobe 6620DT Track (Direct Push)

Dimensions: 10’l x 4’2″w x 13’h/4,500lbs.

Capabilities: Direct Push (5’ stroke), mud rotary, air rotary, hollow stem auger

Scenarios of Use

- Rubber track – ideal for off road and in building/facility operations

- Direct push up to 200’ for soil, groundwater investigation

- Shallow well installation (~50’) in unconsolidated formations using hollow stem augers

- Shallow well installation (~50’) in consolidated formations using air rotary

- Shallow well installation (~100’) in unconsolidated formations using air rotary

Geoprobe 5410 Truck (Direct Push)

Dimensions: 18’l x 9’w x 10’h/15,000lbs.

Capabilities: Direct Push (4’ stroke)

Scenarios of Use

- Direct push up to 100’ for soil, groundwater investigation

Geoprobe 420M Probe Unit (Direct Push)

Dimensions: 28”l x 24”w x 8’h/375lbs.

Capabilities: Direct Push (3’ stroke)

Scenarios of Use

- Rubber tire single axle/ideal for indoor use and tight areas/must have separate liquid fuel power unit

- Direct push up to 20′ for soil, groundwater investigation

(3) Dingo/Geoprobe 5400 Rubber Track Unit (Direct Push)

Dimensions: 8’l x 44”w x 9’h/12,000lbs.

Capabilities: Direct Push (4’ stroke)

Scenarios of Use

- Direct push up to 20’ for soil, groundwater investigation

- HSA 4 ¼ to ~20’

//